Why Prototyping Matters More Than You Think

- Admin

- May 12, 2025

- 4 min read

If you’re building a product—something physical, something you can hold, test, plug in, or turn on—prototyping isn’t optional. It’s essential.

And yet, there’s still a surprising number of people who think a prototype is a one-time thing. Something you whip up quickly, show off to a potential investor, and then move straight into manufacturing. Job done.

Unfortunately, that couldn’t be further from how real product development works, especially when we’re talking about hardware, electronics, or IoT. In this world, prototypes aren’t a checkbox. They’re a journey.

So what is a prototype?

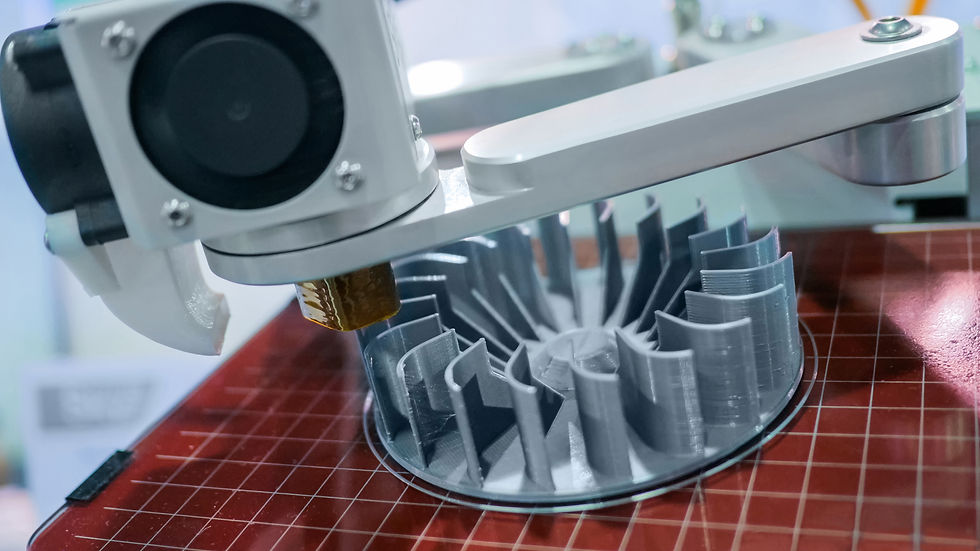

At its simplest, a prototype is an early version of your product. It’s not finished. It’s not perfect. It might be ugly. It might be hacked together from off-the-shelf parts, 3D prints, and duct tape. That doesn’t matter.

What matters is that it works well enough to teach you something.

A prototype is a learning tool. It’s where theory meets reality. It’s where the “what ifs” and “it shoulds” of your design get tested against the messy, unpredictable world of real components, real tolerances, and real user behaviour.

There’s a whole spectrum of prototypes. And we’ll get into the different types—proof of concept, alpha, beta, MVPs—in future posts. But for now, what you need to know is this: no serious product gets built with just one.

That “one prototype and done” myth? It’s dangerous.

Let’s talk about the first one: Proof of Concept

Before we even talk about “the prototype,” there’s usually something that comes before it: a proof of concept.

This is the very first thing you build that shows the idea might actually work. It’s not your final design. It might not even look like your final product. But if your product has, say, a sensor that needs to detect something specific in real time, your proof of concept shows that it can. Not in theory, but in practice.

We’ve built proof of concepts out of everything from cardboard and foam to repurposed consumer tech. The point is not polish. The point is proof.

Because when you’re designing hardware, there are so many unknowns. Will this part communicate with that part? Will the power draw be too high? Will the casing fit around the components? Does it overheat? Does it even work?

A proof of concept gives you a fast, honest answer. And sometimes, the answer is “No.” Which is a good thing, because now you can fix it.

Why prototyping is a process, not a step

Let’s say your proof of concept worked. Brilliant. Now comes the real work—turning that success into something repeatable, manufacturable, and usable.

That’s where prototyping becomes a cycle. Build. Test. Learn. Improve. Repeat.

Each round teaches you something new. Maybe you discover that the internal wiring is too cramped. Or that your enclosure design doesn’t align properly with the PCB. Maybe your prototype works, but only in perfect lab conditions. Not in a hot warehouse, or a cold garage, or with actual user input.

It’s this process—iteration—that makes prototypes so powerful. And so necessary.

Because every time you build a new version, you’re reducing the risk that something will go wrong down the line. You’re finding problems early, when they’re cheaper to fix. You’re saving yourself from that nightmare scenario where you go into production and realise too late that the product doesn’t quite work.

Or worse—it technically works, but users hate it.

But isn’t prototyping expensive?

It can be. But not prototyping is even more expensive.

At CRINNAC, we work with startups and companies that are trying to be smart about their spend. They’re not looking to throw money at fancy enclosures and flashy demo units just to impress someone on Instagram.

They’re looking to learn quickly, test early, and build better.

Prototyping isn’t just about engineering. It’s also about decision-making. What’s worth pursuing? What needs more work? What’s ready for the next stage?

And when you’re building physical products, the cost of a bad decision can be huge. Tooling costs. Wasted materials. Product recalls. Lost customer trust.

Compared to that, a few prototypes? That’s an investment.

You’ll probably need more than one

This is something I tell every new client upfront: building one prototype is like writing one draft of a novel. It’s a start—but it’s not the end.

You’ll need more than one. Maybe three. Maybe ten.

Some will be rough. Some will break. Some will make you question your entire design. And that’s exactly what they’re supposed to do.

Each prototype gets you closer to the product you actually want to release. Not just something that works in theory, but something that works in the hands of real people, in the real world, under real conditions.

And that’s the whole point.

Where we go from here

In our next post, I’ll talk about the different kinds of prototypes you’ll encounter—and when to use each. From proof of concept to MVPs, we’ll walk through how they fit into your development journey and what each one should be doing for you.

In the meantime, if you’re working on a new product and wondering when—or how—to start prototyping, let’s chat. You don’t need a polished design to start. You just need an idea that’s ready to be tested.

We’ll help you figure out the rest. If you want to learn more about prototyping and how we do it, check out our prototyping page.

Comments